For many years, frisbees: flying disks have been a favourite outdoor activity. They are a favorite option for school at the coast, in a park or maybe on one disc-golf lessons. Improving your game and having more fun while playing with a flying disk depends on learning to throw and catch properly. Top Tips and Tricks to Play Flying Disk Like a Pro

For a start, it is very important to grip the disc properly. When you pick up the frisbee put your thumb on top using your dominant hand and let fingers rest underneath it. Be sure to splay your fingers ever so slightly when releasing the disk. Step forward with your non-dominant foot when you are ready to throw. As you are throwing the disk, end your throw with a flick of the wrist to get some last spin on it and make that flying disk go sky high.

Flying disks, also known as Frisbees after the brand name that popularized them, are not just toys for dogs and beachgoers. They have a fascinating history and come in many shapes and materials that serve different purposes. Whether you throw them for sport, exercise, or leisure, flying disks can provide hours of entertainment and inspiration.

The origins of flying disks can be traced back to ancient civilizations that played disc games with stones, shells, or bones. In the 19th century, a Canadian named Walter Frederick Morrison invented a plastic disk he called the Pluto Platter, which he sold to a toy company that renamed it the Frisbee. The name came from a famous pie company in Connecticut whose empty tins were used by college students as makeshift targets for throwing. By the 1960s, Frisbee catching had become a popular pastime and sport, with official rules and competitions. Today, flying disks are made by many brands and used for various purposes, from ultimate flying disc to disc golf, from freestyle routines to trick shots.

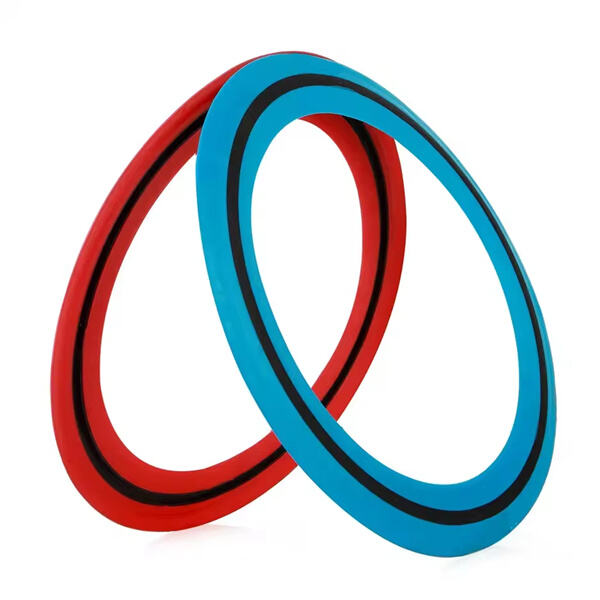

The design and construction of flying disks vary depending on their intended use. Some are made of lightweight plastic or foam and are easy to catch and throw, especially for beginners or children. Others are made of heavier plastic or rubber and require more skill and practice to handle, as they can fly longer, farther, and faster than their lighter counterparts. Some have a smooth edge for a fast and stable flight, while others have a concave or beveled rim for better grip and spin. The colors and patterns of flying disks can also affect their visibility and style, making them more attractive or distinctive.

The benefits of playing with flying disks go beyond their fun and social aspects. They can improve hand-eye coordination, balance, agility, and cardiovascular fitness. They can also boost cognitive skills like concentration, problem-solving, and creativity, as players have to adjust to the changing conditions of wind, slopes, or obstacles. Moreover, they can foster teamwork, sportsmanship, and environmental awareness, as players learn to share the space, respect the rules, and clean up after themselves.

1. Factory Audit: BSCI and Sedex4P. update every year. Major Brands like Walmart, flying disk and Coca Cola.3. We can accommodate small-scale orders that custom. support small business if you are just an entrepreneur in this product range4. A comprehensive company system support the design of large-scale projects.

1. will provide prompt comprehensive support our customers. We start our commitment before make sale, by flying disk wide range tailor-made solutions to fit the needs every project. experienced team is close contact with clients ensure their needs are addressed and understood.2. After the purchase after sale, be there for our customers, giving uncompromising assistance. If there any issues, we guarantee a response within 12 hours. goal is providing fast and efficient resolutions, ensuring minimal disruption to your operations.

We'll provide most affordable prices based on different needs of customers. Flexible pricing ensures every customer receives service that tailored their needs. By studying and analyzing each client's flying disk needs, can provide cost-effective options without sacrificing quality or service

Three departments involved in the process: Injection Department, Assembly Workshop Purchase Department.Injection Department:Flying Disc InjectionPQC (Process Quality Control).Pass for Heat Transfer Printing in the Assembly Workshop.Failure: Sent DestructionPurchase Department:IQC (Incoming Quality Control) a process examining printing and Packaging Material:The Assembly Workshop where you will find the process Heat Transfer Printing.Fail: Sent for Destruction.Assembly WorkshopHeat Transfer PrintingGo on packing using the polybag. Then flying disk it in the outer carton.Failure: Sent for DestructionFinal Steps:Polybag packing and outer cartonFinal Quality Control (FQC)Pass: Ready to Ship.Failure: Sent for DestructionThis ensures the quality of the product throughout the process and also handles damaged items by destroying them.